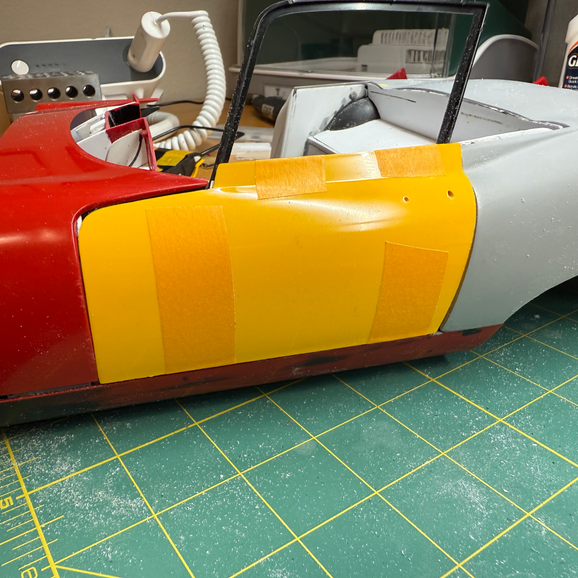

Update on door framing

in 1/8 Revell Jaguar E-Type

Well that was “fun”. I have spent most of the last week or so trying to get a positive locating mechanism for the inner and outer door skins. I need to get the doors properly located in the door openings before I can fit fhe hinges. So let’s talk door skins. The kit has an outer door skin with a thick pin/thin pin locator for the inner door skin. One side fits fine, the other doesn’t. I know, shocking right?

The kit inner door skin has cuts in it to receive their goofy hinges. For the “real” kit, all of that is positively located, even if it’s ugly. But in my case there is no fore/aft location between inner and outer door skins. There is also no way to keep the outer skin aligned with the inner skin. In the pix above you can see I cut slots into the inner rear door faces for magnets to “latch” the door when shut.

The entire fit is <ahem> “casual”. So I had 3-4 goes at providing some inner structure to the doors, as well as positively locating the skins. I thought I would build some structure to “capture” inner skin and hold it. That was stupid because of all the curves. I have 3+ degrees of freedom within the physical constraints of the rear door jambs and fronts. So… this

I added styren to “fill” the gap between the inner and outer skins forward of the A-pillar line and a curved strip of styrene to prevent the outer door skin from sliding past the inner. That worked. Then I spent a couple of hours sanding and test fitting the doors. Here’s where I ended up…

the inners and outer are positively located and I used paper tape to lock them together for fitting into the door frames. I ended up doing a lot of sanding on the rear door jambs. They intruded a little too much, but I was able to shave them down. I will still neeed to trim a little more here and there, and on the driver’s side I will need to “fill” the gap you can see. For some reason the floor isn’t lining up as well as I’d like, but I can get around that.

Now I know everything fits, and I know where I need to mount the hinges on the front kick panels. The mounting points inside the outer door skins are going to need a little work, but we’re going to have fully functional doors. <sigh>

Cheers,

Chris